Emmanuel Timothy, Senior Project Engineer, BAC Middle East L.L.C. and Rafael Van Eijcken, General Manager, BAC Middle East L.L.C., write on the actual savings that can be unlocked from opting for Eurovent or CTI certified cooling towers compared to cutting cost with undersized cooling towers.

Although cost is a critical consideration for customers, there is a need to encourage a more holistic procurement strategy that considers long-term savings over first-time payments. The initial cost is not the best, nor should it be the only measurement of the product’s true value, especially when it comes to critical HVAC equipment such as cooling towers, where the performance and operation will be responsible for the majority of the total cost in the long term.

This issue becomes very applicable and visible when choosing between certified or non-certified equipment. Certified equipment differs from non-certified equipment not only in terms of the initial purchase price, with the former typically being more expensive, but also in terms of size, weight, performance, and other aspects. The reluctance of some stakeholders to invest in Eurovent or CTI-certified cooling towers is primarily due to the need for more awareness and understanding of the value it offers to their bottom line in the long term. However, having a clear understanding of the importance of certification and the available supporting tools for customers to verify and choose certified models would help prevent the selection of incorrect cooling towers, which will have severe consequences due to performance issues in the installed site.

To provide background, Eurovent Certified Performance (ECP) Programme’s main aim is to promote fair competition and provide customers with reliable information about the performance of equipment in the market. To achieve this, manufacturers’ claims regarding product ratings are verified through independent testing of randomly selected production models in external laboratories. The objective is to ensure that each certification program is effective and trustworthy enough for the market to recognise and demand ECP-certified equipment when making investment decisions. Eurovent, in collaboration with the US Cooling Technology Institute (CTI), has developed a certification program specifically for the thermal performance of factory-assembled open, and closed-circuit cooling towers. These program models consist of individual units with published thermal rating capacities and associated input fan power levels.

Looking at the numbers

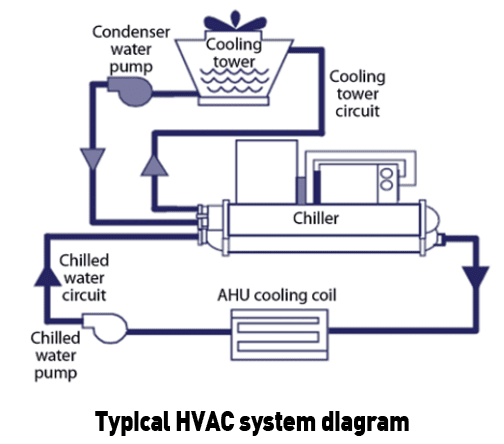

Let us consider a typical example in the Middle East of an HVAC application that operates year-round with a load variation from 100% in summer to 75% in winter. The summer condition to cool 100 LPS from 40°C to 35°C at an ambient wet bulb temperature (WBT) of 32°C. In this case, the cooling capacity to be rejected would be 2.093 KW.

For this scenario, the selected cooling tower, which we can refer to as Cooling Tower A (CT-A), will have a length of 2.585 mm, 5.500 mm wide and 3.653 mm high with 29 KW absorbed fan power and a 30 KW installed fan motor. The overall sound power level of CT-A would be 104 dB(A).

Now, let us consider an undersized model Cooling Tower B (CT-B), which would only deliver 85% but with a lower initial cost than CT-A. Typically, this unit would be 15% smaller in physical size or have the same size as CT-A but with an absorbed fan power of only 20,1 KW with a 22 KW installed fan motor. The overall sound power level of the CT-B would be 102 dB(A).

For 2093 KW, which has to be dissipated at WBT 32°C, CT-B will supply a 1,35°C warmer outlet than designed. Or it will deliver the design temperatures up to a WBT of 30,79°C only.

For projects where undersized cooling towers are installed, which are also typically non-certified cooling towers, when customers face a shortage in capacity and contact that cooling tower manufacturer about the problems faced on site, the response will typically be that the supplied cooling tower is ‘correctly sized’ and that the issue is most probably related to poor operation and maintenance. This risk is taken by some manufacturers in the belief that the customers will not make an effort to request and/or verify third-party certification documents, as their main priority is choosing a system with the lowest initial cost. Initially, the problems caused by an undersized cooling tower unit might be minimal until the project requires its full cooling load which may take several years. In time, however, the problem of capacity shortage will be aggravated and create serious problems onsite.

Although the customer may be misled by small power savings on the fan motor KW for CT-B compared to CT-A, they may not be aware that such an undersized cooling tower will trigger extra work on the chiller by increased compressor lift linked to the 1.35°C warmer water supplied to the chiller by CT-B. This increased compressor work increases the chiller power consumption significantly during a year-round operation by more than 6%. With the chiller compressor motor being a multiple of the CT fan motor, this situation causes significantly higher operational costs for the customer.

Let us also look at the annual economic impact the customer will face with CT-A and CT-B if both cooling towers use variable frequency drives and run with a water concentration factor of 5 cycles.

The fan kWh requirement-based year-round operation for CT-A will be 55.540 kWh, and for CT-B, it will be only 50.800 kWh. However, looking at the electrical energy needed for the chiller, for CT-A, we need 1,114360 kWh, but for CT-B, the chiller requirement goes up to 1.178.700 kWh, which is 6% more.

Therefore, by adding the chiller and fan kWh the CT-B system still needs 5% more electrical energy annually. A typical 0,38 fils/kWh AED cost will represent an annual operating cost of 22.648,00 AED.

In addition, CT-B will have more water consumption, as the chiller will need to work harder, and therefore more waste energy is dissipated, resulting in more water evaporating. Ultimately, the CT-B water consumption will be 300 m3 [65.991,00 Imperial Gals] water more than CT-A. Considering the water rate at 4,6 fils/IG AED (plus the sewerage charges) this will add approximately another 4.500,00 AED per year.

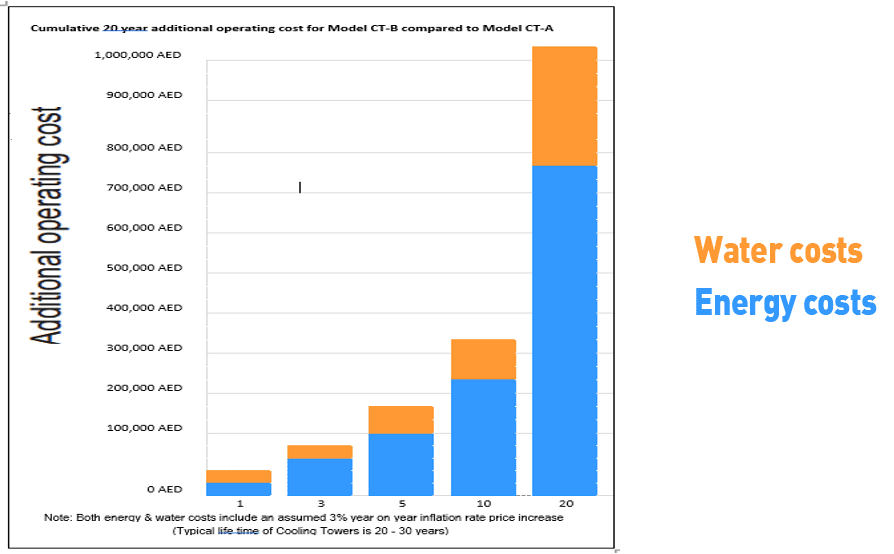

Below is a chart illustrating the additional cost vs energy and water costs with a 3% year-on-inflation rate price increase.

The total operating cost difference for water and electricity for the system with CT-B will be 27.148,00 AED. This number is typically near to half of the first cost difference with CT-A. From this, it is clear that a small price advantage for CT-B melts away when considering energy and water costs.

Keep in mind

Thus, it is essential to remember that value for money does not just come by looking at the first cost and mindlessly accepting manufacturer documents with self-declared thermal performance. A customer must be able to challenge such manufacturer declarations by questioning whether the thermal performance is Eurovent/CTI certified or insist on a performance field test (acceptance test) according to the Eurovent/CTI standards to confirm or verify the declared thermal performance.

Only by insisting on a field performance test carried out by certified testing agencies, even with the additional cost, will the customer determine whether the cooling tower can provide the listed performance. However, suppose the results lead to a failed test. In that case, the customer’s misery will just begin, as this often leads to many unpleasant discussions with the manufacturer, often with no final resolution. Selecting a cooling tower which has Eurovent / CTI Certified Performance via either the third party or internal lab testing ensures the buyer before the purchase that they will not have higher operating costs due to underperformance. Certified thermal performance testing removes risk towards system economics and removes the guesswork. It also removes the problems of litigation, penalties and compensation should an already purchased product be found to underperform because it’s too late by then.

Remember to look for the Eurovent / CTI Certified Performance mark to ensure optimal cooling tower selection. Eurovent includes yearly factory certification conformity audits of the Cooling Tower manufacturer. At the end of the day, purchasing a Eurovent / CTI-Certified model ensures that the cooling tower will perform as specified. In all instances of thermal certification, the purchased model, or a model within the same line, will have been thoroughly inspected and tested by a Eurovent / CTI-licensed testing agency, and customers can rest assured that their system will operate as intended.